Written by Lucas Weakley

New Technology

As seen in the Winter 2019 issue of Park Pilot

An indispensable material that I’m sure you’ve used in almost all of your model aircraft builds is tape—whether to hinge a battery door, secure some wires, add skid protection, or add some visual appeal. I’d argue that tape is a ubiquitous part of our hobby.

In this article, I want to highlight a few unique tapes and their applications when constructing foamies and park flyers. These tapes fall into two categories: functional and aesthetic. Functionally, tape can add wear resistance, waterproofing, structural strength, and rigidity to typically delicate foam airplanes. Aesthetically, tape can be used to add vibrant colors and textures that aren’t normally seen in foam stock, such as making a foam airplane look like it’s made of metal.

I won’t discuss covering films. That topic is well covered (pun intended) by balsa modelers who are more versed in the process than I. Instead, I want to focus on the quick, easy, durable, and versatile applications that self-adhering tapes can bring to park flyers.

I find myself often turning to regular packing tapes to strengthen my models. Foam airplanes can mar easily when taken to the field or while being worked on. If I know a model will be prone to getting beaten up (usually because it’s a fun flyer), I might preemptively cover its most susceptible areas with an overlapping shield of packing tape.

My go-to variety is 3M Scotch Heavy Duty Shipping Packaging Tape (scotchbrand.com). This tape is thick and offers good surface protection. With overlapped edges, it can create an impermeable barrier to water. It’s also incredibly sticky and does not stretch, making it easy to apply on flat surfaces, but it can sometimes be tricky to wrap around curves. Because it is strong, this heavy-duty packing tape can add rigidity to foam structures by covering them in a skin of tape.

This application of tape is comparable to using composite materials (which I discussed in my Fall 2018 column). Covering high-stress foam surfaces with a rigid skin transfers the bending and shear forces through the skin instead of the foam beneath, while also protecting the foam from surface damage, dirt, and water.

Another tape I use often is fiberglass-reinforced packing tape. This tape is thin, supple, and embedded with either parallel inline ribbons of fiberglass or a woven grid of fiberglass fibers. This tape is most useful for constructing hinges and reinforcing wings spars or control surfaces.

The fibers in the tape make it almost impossible to tear, so it is great for parts that frequently move such as control surfaces and canopy hinges. The fiberglass makes this tape incredibly stiff in tension. Applying it to the top and bottom sides of a lifting surface will add bending resistance, even without a spar, and can strengthen any sandwiched stiffeners.

From bottom: Fiberglass packing tape; white, blue, and black carton-sealing tape; duct tape; and aluminum tape. Not shown is heavy-duty packing tape.

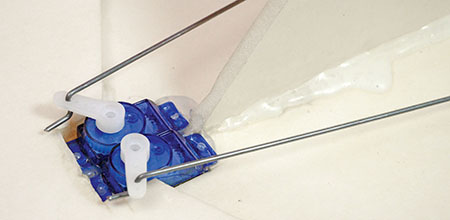

The fiberglass-reinforced tape that Lucas likes the most has this woven pattern, which helps prevent tearing. This version also contours over curves better than straight, parallel fibers.

This tape is also great for securing wires where normal packing tape isn’t flexible enough. Duct tape can be used to strengthen aircraft in these scenarios, but the fiber-reinforced packing tape is lighter and stronger, and its adhesive is better suited to stick to foam.

Finally, if you’ve ever used paper-backed foam board, you’ll understand the importance of weatherproofing your models. Even the smallest amount of moisture can weaken the paper’s bond, and dirt or grass can easily stain the surface.

Depending on the airplane, covering it entirely with heavy-duty packing tape would be too heavy and make it unnecessarily rigid. Lighter aircraft can be coated with carton sealing tape. This tape is extremely thin, lightweight, and is as impervious to water and dirt as any other plastic. Carton sealing tape is easy to apply and can be laid onto raw foam board before construction. Simply close off any open foam edges after cutting and gluing the model together.

Clear carton sealing tapes have an off-white look that might be unappealing, but you can protect your foam airplane from the elements and make it look good with my next suggestion.

Carton sealing tapes are made in a bunch of vibrant colors! The colored variety of these tapes is equally waterproof and lightweight. The use of colored tapes was popularized by Ed from Experimental Airlines (youtube.com/user/ExperimentalAirlines). I also showcased these tapes in my Maker Hangar series. The best place I’ve found to purchase these colored carton sealing tapes is from Tape Brothers, which now sells on Amazon (amazon.com/l/2601810011).

My only complaint is that the tapes are not fully opaque. When held up to light, colored carton sealing tapes are thin and translucent because the pigment is in the adhesive. When these tapes are overlapped to cover a sheet of foam, the overlapping areas are visibly darker when contrasted on the white foam board.

To solve this, you could butt the tape strips against each other instead of overlapping them, but this will reduce the surface’s water resistance. You could also limit the use to the white, gray, and black, which are more opaque and don’t contrast with overlapping areas. I usually mix these techniques by covering my foam with opaque white or black tape and using other colors to add accents. Alternatively, Radical RC (radicalrc.com) sells a selection of opaque acrylic tapes that can be used in place of carton-sealing tape in most cases.

Another visually appealing look can be achieved with metallic tape. Inspired by the charcoal chrome vinyl wrap of the Virgin Galactic SpaceShipTwo’s tailbooms, I’ve always wanted to replicate that look on my models. I’ve found that Top Flite self-adhesive trim sheets (monokote.com) work well to replicate the appearance and are inexpensive enough to cover small airplanes.

While researching my SpaceShipTwo-inspired finishing technique, I discovered a tape even more visually tantalizing than chrome.

A more convincing metallic look can be achieved by using real metal tape! A company called Flite Metal (scaleaero.com/flitemetal.htm) makes thin aluminum tape for use in model making. It has been used on some visually stunning builds. Come to think of it, most of my airplanes have a high enough thrust-to-weight ratio that I’d be able to cover them in normal hardware store aluminum tape.

Regardless of the product choice, adhering aluminum to a model allows for polished, brushed, or pearled finishes, imitation rivets, or anything else you’d find on a full-scale aluminum airplane. This is probably one of my favorite modeling techniques that I’ve stumbled upon recently. A quick Google search for “aluminum tape RC modeling” yields some breathtaking builds that are sure to be inspirational.

Lucas did some tests using aluminum tape. Top right: Pearled with a Dremel (he’s still working on the technique); left: brushed with Scotch-Brite abrasive pads; bottom right: quickly polished with compound, it still has some scratches.

If I’ve learned anything from my modeling experiences, it’s that tape can often be an overlooked tool with tons of potential applications. As a foam aircraft modeler, I don’t know how I would build most of my models without these rolls of sticky plastic, paper, and metal.

I hope by letting me geek out on this topic that you’ve also learned about a few types of tape that might find their way onto your future aircraft when you’re in a sticky situation!

The overlapped joints of the blue carton sealing tape are easy to spot in this picture compared with the more homogenous colors of the black canopy and white wings.

By Lucas Weakley | [email protected]