Choosing the right glue is like picking the right tool for every job. Article and photos by Michael Ramsey. Featured in the Spring 2008 issue of Park Pilot.

The prime directive for an adhesive is to stick. One or more of four basic materials are used to construct most park models, and there are adhesives that will and will not work with them. Fast-drying adhesives are popular because they let us build quickly, although slow-cure types often have the advantage of a stronger bond, and should be strongly considered when the joint is critical. Be sure to read and understand the warning labels on any adhesive chosen, and always work in a well-ventilated area.

CA adhesives come in a variety of sizes and types to join many different materials.

Gluing wood: Cyanoacrylate (CA) adhesives are very popular for wood, and several formulas are available. Thin CA should be used to bond parts with tight fitting joints. Its watery consistency permits the adhesive to wick into the joint and permeate the material. Thicker viscosity formulas are great for high stress areas or adding a fillet of material as reinforcement. Note that spray accelerator should be used sparingly, and only after the CA has had time to saturate the joint. Common high-stress areas in a model airplane are the motor mount, battery and servo trays, tail sections, landing gear and wing mounts. The adhesive most often used here is Epoxy. Different curing times are offered, and 5-minute is not as strong as a 20-minute formula. Epoxy and CA cure through chemical reaction, which often speeds the building process. Wood glues are good options; they have low odor and clean up with water or alcohol.

Epoxy is the ideal ticket for high-strength joints in high-stress areas. Common varieties yield roughly 5-minute, 15-minute and 30-minute working times. Full chemical curing often takes somewhat longer.

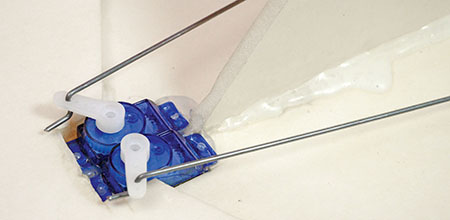

Gluing foam: Bead or smooth foam is flexible, so flexible glue is recommended. Brittle glue joints eventually fail, not because the glue breaks but because the foam outside the glue joint tears away. There are special CA formulas for foam, labeled either as foam-safe or odorless. Standard CA formulas will dissolve most foam materials except for some of the rubberized molded types. Be sure to use foam-safe accelerator spray. Epoxy will work to join foam, but it’s heavy and the yellowing after cure is a gruesome sight. Many white glues (aliphatic resin) dry clear and blend in. Low temperature hot glue is often considered the best adhesive for bonding plastic, metal, wood or anything else to foam. It’s very handy for securing servos.

Foam-safe CA and accelerator are handy for use on foam parts. Always test for compatibility before use .

Gluing plastic: Not all plastic can be repaired or bonded. Most plastic “whites” when flexed, so if the plastic is whiter in color at the damaged area, it will bond with most adhesives and plastic cement. Test the glue on a hidden area. Scuff with medium-grit sandpaper to improve grip. CA and contact cement are good choices for the plastic parts on most park models. Very little adhesive is needed because plastic is non-porous. Canopies and windscreens should be attached with clear-drying white glue or polyvinyl resins like Pacer Formula 560. CA can damage the plastic and fog the inside. Scuffing these surfaces improves bond.

Secure micro servos with Low-Temp Hot Melt Glue from Woodland Scenics.

Gluing composites: Fiberglass, carbon fiber and Kevlar mixed with resin are often used to make landing gear and other structural parts. CA and epoxy work well here. Again, scuff the surface, and clean with alcohol for the best bond. If a repair is necessary, consider layering the fracture with a splint material like fiberglass cloth or carbon fiber. Thin CA is a wise choice for penetrating deeply into broken joints and tacking parts back into place. The splint can be added with either thick CA or slow-setting epoxy resin for the best penetration.

Article: